Hubs to Dies

Sources

Search

Contact

Home

The VAMs

What Is A VAM?

Interest & Rarity

Hubs to Dies

New VAM Variety

Obverse Dies

Reverse Dies

Clashing

Hubs versus Dies

Without going into too many details that would take much longer and much more space, understanding the basic difference and use of hubs and dies is helpful. Today the transfer of images from working models of a coin to the final die is automated with the benefit of technology that was unimaginable in 1881. It is unlikely that the Mint worker of 1881 could even grasp the processes in use today.

In the creation of dies used to stamp out coins there is a multi-stage process that starts with the creation of a relatively large working model of the coin carved by an engraver.

Through the use of a device much like a standard pantograph, the size of the working model is reduced to the size of the final coin. In 1881 this was mechanized, but with what we would consider to be a crude mechanical lathe today. The resulting product of this process is known as a master die. The master die is too precious to be used for stamping coins, so its image is transferred as a positive image to another piece of steel known as a hub.

The hub is a positive image of the final coin, but to stamp the coin you need a negative of the coin. So the hub is then stamped into another piece of steel to create a negative working die. (There are more working steps in this process, but this is the high level view.)

In the course of creating the needed positive and negative images there are several opportunities to introduce minor variances in the dies. Unintentional errors, doubled features, and other issues are possible at every stage. The result of this process is obviously seen in the final struck coin.

Since the process is repeated for both the obverse and reverse of the coin you can have dies with different characteristics paired to create varieties. Another critical factor is wear. Wear can cause the replacement of a die, resulting in a different pairing. But wear can also introduce cracks, breaks, chips, rust, excess polishing and other recognizable features. Often as pressmen recognized that there were issues a die would be taken our of service, polished and put back into service in a slightly altered condition.

Quality control should catch all this and reject the coins. But in the New Orleans Mint apparently this was not a well executed process. The working conditions, lack of management oversight, and belief that the coins would never make it into circulation all contributed to the retention of poorly executed coins.

For a more detailed discussion of the process see the section on Making VAMs.

Obverse Hub

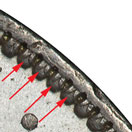

There is only one hub (type III) and one sub-variety (2) for the obverse of the 1881-O coins. Type III characteristics are highlighted in red, and sub-variety 2 characteristics are in blue.

Reverse Hub

There is only one hub (type C) and one sub-variety (3) for the reverse of the 1881-O coins. Type C characteristics are highlighted in red, and sub-variety 3 characteristics are in blue.

Getting Started

Collecting The 1881-O

The 1881-O VAMs