January 2020 - Welcome

Sources

Search

Contact

Home

Welcome

Click on year to expand

2022

2021

2020

2019

2018

2017

2016

2015

Welcome

Die Fingerprints

Never Stop Learning

As we ended the year and look back a lot happened and we can only hope that there will be an equal level of activity in 2019.

![]()

![]() VSS Submissions

VSS Submissions

We have four coins to send to Leroy for analysis and that needs to get going in January. Hopefully there is a little something new in the group.

![]()

![]() Big Goals for 2020

Big Goals for 2020

Die Fingerprints

This has become a never ending project and might always be so because later die states are always emerging. But we have coins that need documenting and that will be one focus.

See the notes in the next column on our work for January.

VAMworld

We have a number of items to clean up from the O Set Left Study and we hope to do that early in the year.

![]()

Pricing Update

Once each year we burn the midnight oil and update prices here to maintain a historical record. We use current PCGS prices as of December 31, 2019.

![]() We often grumble about the prices realized for coins, and it looks to us like 2019 was a year to grumble, and grumble loudly. Usually investing in high quality anything, especially coins, tends to help hold values.

We often grumble about the prices realized for coins, and it looks to us like 2019 was a year to grumble, and grumble loudly. Usually investing in high quality anything, especially coins, tends to help hold values.

But 2019 was an awful year for the upper end of the 1881-O series. We have had movement in the past that was reflective of economic conditions in general, but this was not a good year except for the lower grade coins. But from a cost standpoint doing well in cheap coins while doing poorly in higher grade coins is not a formula for success.

To see the analysis click here.

![]()

How much did we drive the market?

In 2019 we really slacked off with our purchases and in particular purchases in higher grade coins. We have such a large inventory that it is difficult to tell how much we have affected the market in the past, but this year we could not have done much.

![]()

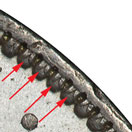

Our die fingerprints seem to come in handy when we just get stumped on coins and associated VAMs. They also prove to be handy for new collectors and so we continue down that path.

This month we went back and looked at several coins to finish up those analyses. First was the VAM 1D - Flaky Eye.

None of the coins in our inventory showed any die cracks regardless of grade. We have twenty-Four coins spanning from VF-35 to MS-64 and they all lacked any die cracks or breaks.

![]()

However, on VAM 1F - Pitted Obverse Right Field and Eagle there is a slightly different story.

There is the beginning of a die crack above and below the "E" in in "E PLURIBUS UNUM". This is a VAM to watch moving forward to see if this developed further.

![]()

We also looked at VAM 1G - Die Gouges Inner Wing #1 and there found no die cracks on either the obverse or reverse.

![]()

It has been requested that we look at VAMs 37, 37A, and 37B for die cracks. This is a good place to start off in February and we have quite a bit of material. Between the three VAMs we have 25 coins and most are either AU or MS states and should be easy to check.

![]()

Along this journey you encounter bits of information that turn on light bulbs and help you understand the ins and outs of the making of coins. I always enjoy discussions with Roger Burdette because of his knowledge and depth of research.

Away from the Morgan world on another research project for the Stone Mountain Half, we encountered some doubling on a lot of coins in a series and sought some clarification from Roger. What made this doubling confusing was we were seeing some doubling from repunching of lettering, plus some doubling that appeared as "steps" on other lettering and devices.

![]()

Here is Roger's complete insight, which clarifies a lot and since I believe (still verifying) we have also seen this on Morgans I thought we would share.

"We usually think of a 'doubled die' as occurring when the hub is slightly misaligned with the die during one or more blows of the hubbing press. This is a sound explanation for most doubled die products visible on coins.

But doubling on a die can also occur due to heating/cooling stress on the die steel. This is especially prevalent when the steel is of uneven density or the alloy is not fully mixed. William and Charles Barber both explained that the process of hardening and tempering steel dies could easily change the die radius. Naturally, if a hub had a radius of 25, and an incomplete die had a radius of 23 after softening, there would be a partial misalignment between the two - with the hard hub usually obliterating the earlier discrepancy. But, this smoothing out did not have to occur with all dies made from the same hub, or with all designs.

The differences are tiny, but sufficient to cause multiple fringes or 'steps' around inscriptions or other relief. Rather than actual 'repunching' (an intentional action), these were inadvertent, and largely uncontrollable metallurgical changes. As steel technology improved, less of this would be noticed, but up to the era of machine cut dies, it was always possible.

Further, it was standard engraving department practice to clean up (touch up) working dies before use. This was mostly to remove slight burrs and other small defects. The last US coins to which this was routinely applied were the 5-oz silver 'quarters' mandated by Congress. Every die had to be manually cleaned and retouched to remove cutting defects."

![]()

Getting Started

Collecting The 1881-O

The 1881-O VAMs